Please join us on Tuesday, April 9, at the ASHRAE Boston Product Show, at the Marriott Boston Quincy (1000 Marriott Drive, Quincy, MA 02169). Come find at us at...

Read More

Buckley is hosting technicians from Environmental Systems, Schneider Electric, and ENE Systems at our training facility this week to become certified technic...

Read More

Get to know the Buckley Team: Meet Tina Ruidiaz, she is Buckleys Accounts Payable Coordinator. Tina has worked at Buckley for 10 years, currently in her positi...

Read More

Buckley Associates is providing a comprehensive 30-minute refresher on our 42 diverse and complimentary product lines. While Price and Greenheck are our two big...

Read More

Congratulations to Brandon Dearth on his recent promotion to Assistant Estimating Manager!Brandon has consistently demonstrated a high level of dedication to th...

Read More

Buckley helps their employees put their best foot forward with an on-site visit from the Red Wing Mobile Shoe Store. #employeeappreciation...

Read More

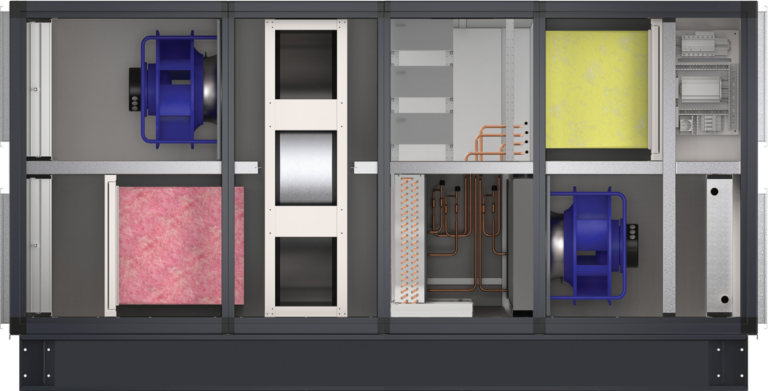

Ideal for Passive House Projects The Systemair Geniox+ is a fully customizable, high-quality, modular air handling unit that can fully integrate with third-part...

Read More

One Design Center is currently undergoing a life science focused renovation. As part of a vivarium fit out, Buckley worked with AHA Consulting Engineers and PID...

Read More

Ahoy from the Goldeneye! Captains Dean Lees & Vincent Maccarrone hosted our friends at AHA Consulting Engineers for a boat cruise and education session on a...

Read More

https://vimeo.com/836934931 Introducing Opti-Lok, a filter enhancement technology which increases a filters ability to remove fine particulate. When applied to ...

Read More

ASHRAE recently published 241-2023 Standard - Control of Infectious Aerosols for maintaining healthy indoor air quality (IAQ). This Standard establishes minim...

Read More

Sensible Fan Coils, DOAS Fan Powered Terminals, Chilled Beams, Displacement Systems Thursday, July 27 10am-3:30pm Exposed Perimeter Chilled Beam project in Camb...

Read More